CNC wire and flat stock bending machines

Bend wire and flat stock with precision and speed using our industrial CNC bending machines

Discover our 3D wire bending machines

Our 3D wire bending machines offer great production flexibility. Ideal for small and medium series, they can bend wire from coils or cut-to-length bars, with low tooling costs and quick setup. Their 3D graphical programming and touchscreen interface ensure easy operation and seamless integration into your production cells.

Robomac e-Motion

From Ø.08″ to Ø.375″ / Ø2 to Ø10 mm

100% electric bending machine, fast, precise and versatile. Ideal for optimized cycles.

Learn more

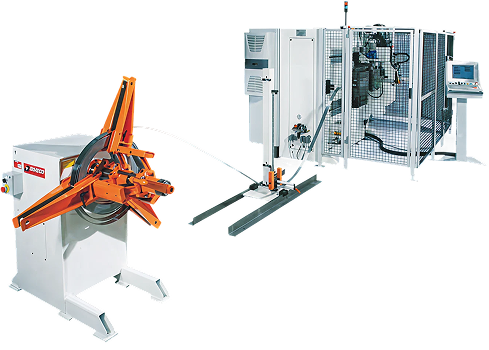

Robomac TF

From Ø.08″ to Ø.625″ / Ø2 to Ø16 mm

Robust, high-performance machine, world-renowned for years of proven reliability.

Learn more

Robomac TFE

From Ø.08″ to Ø.625″ / Ø4 to Ø16 mm

100% electric, with high precision and short cycle times

Learn more

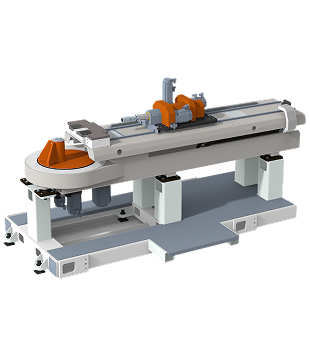

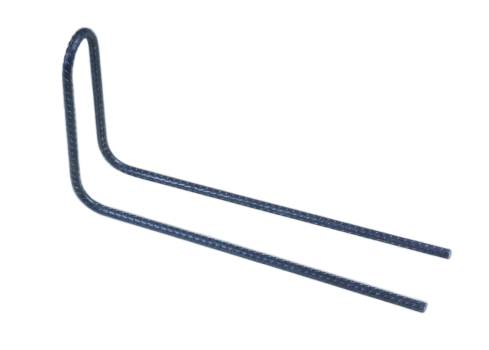

Robomac 2 heads

From Ø.065″ to Ø.47″ / Ø1.8 to Ø12 mm

Double head for long lengths, with close bending thanks to a retractable central head.

Learn more

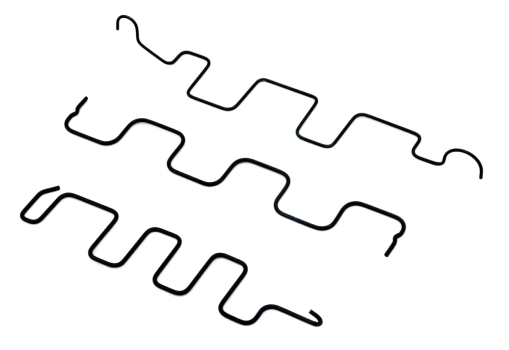

Robomac 4 heads

From Ø.07″ to Ø.16″ / Ø1.8 to Ø4 mm

Exceptional cycle times thanks to 2 parallel benches and 4 simultaneous folds.

Learn more

Numabend T815

From Ø.16″ to Ø.51″ / Ø4 to Ø13 mm

Compact and easy to integrate into agile cells, for forming wire and tube from coils or bars.

Learn more

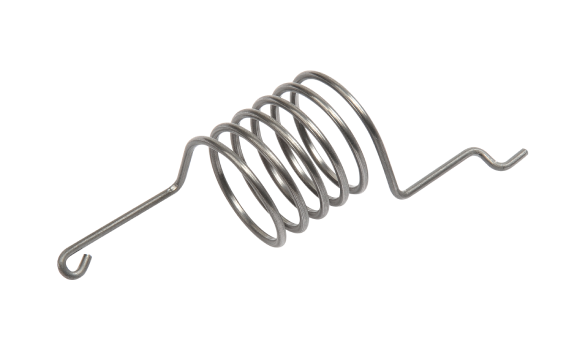

FRX

From Ø.03″ to Ø.25″ / Ø0.8 to Ø6 mm

Compact, flexible machine, ideal for spring coiling.

Learn more

F46 / F47S

From Ø.04″ to Ø.28″ / Ø2 to Ø7 mm

100% electric, fast and precise, for small or highly developed parts.

Learn more

F37SP

From Ø.08″ to Ø.16″ / Ø2 to Ø4 mm

3 digital axes, cut after fold: ideal for short lengths and excellent repeatability.

Learn more

FPX Busbar

From .35×.12″ to .98×.31″ / 9×3 to 25×8 mm

The precision solution for your busbar production

Learn more

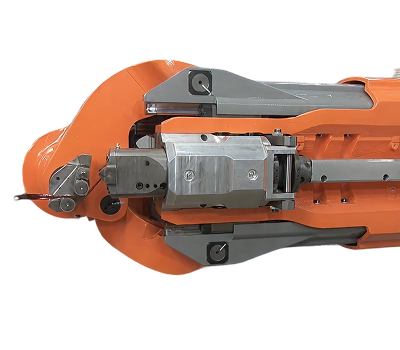

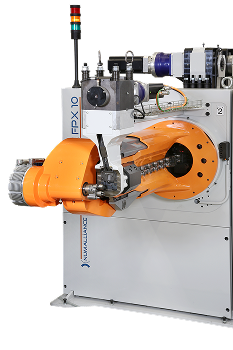

FPX

From .35×.12″ to .47×.16″ / 9×3 to 12×4 mm

The precision solution for flat bending with secondary operations

Learn more

FTX

From Ø.12″ to Ø.625″ / Ø3 to Ø16 mm

Thanks to an arm that can move around the wire, the FTX allows for slip-free folding and double folding.

Learn more

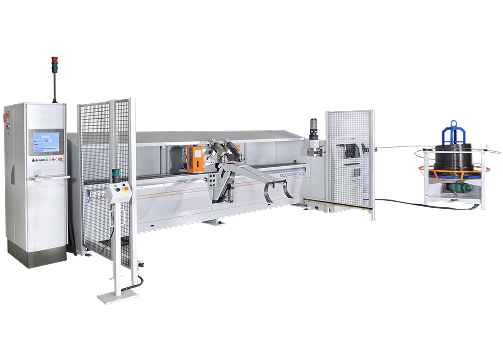

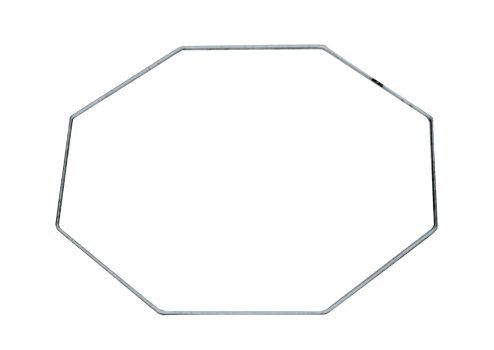

Discover our 2D wire bending machines

Our 2D wire bending machines are designed for long, symmetrical or complex parts with tight bends. Easy to program, they ensure excellent repeatability and smooth production, even for the most demanding geometries.

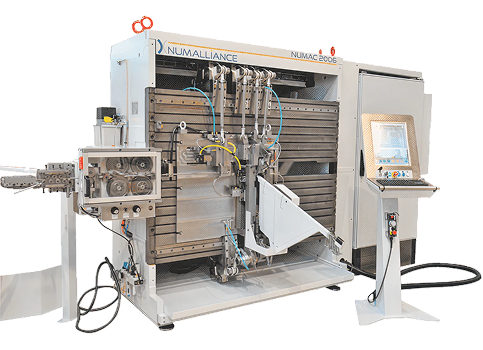

Discover our CNC multi-slide machines

Directly evolved from mechanical multi-slide machines, our CNC multi-slide machines combine speed, repeatability, and robustness to meet the demands of high-volume production. They offer fast tooling changeovers, a clean production environment, and can be fully customized to your specific needs.

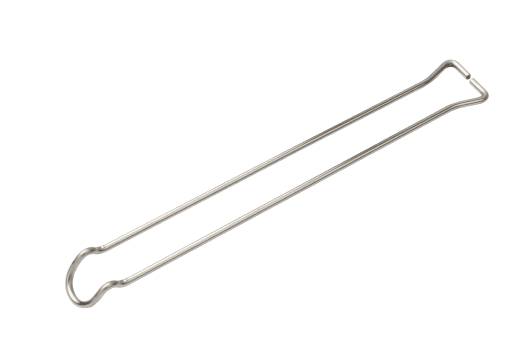

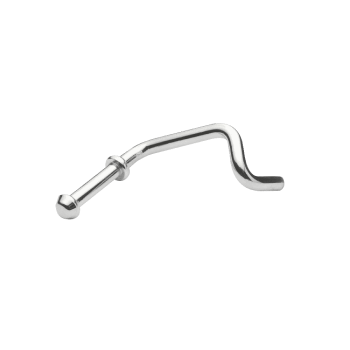

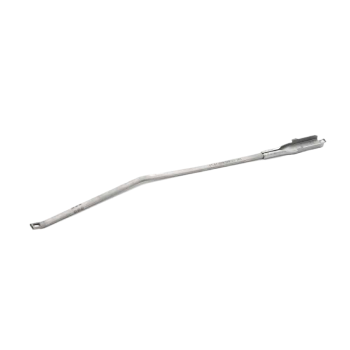

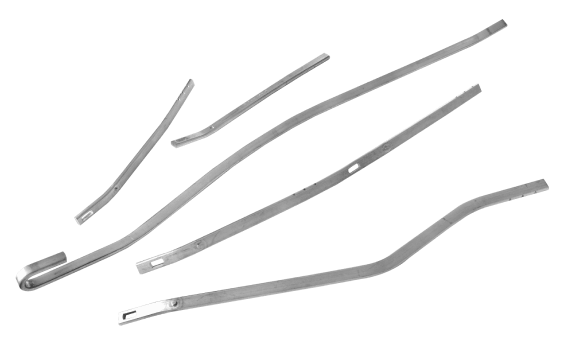

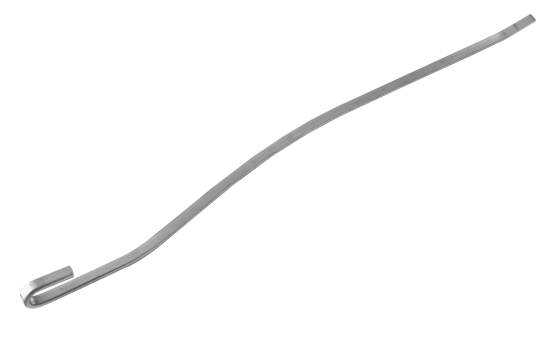

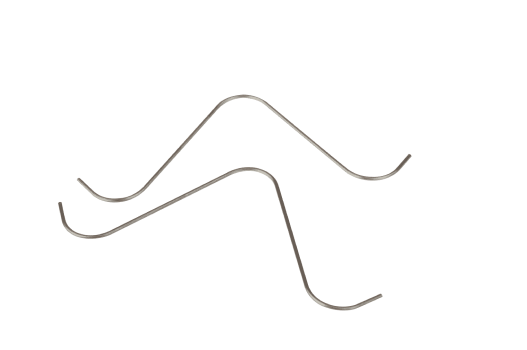

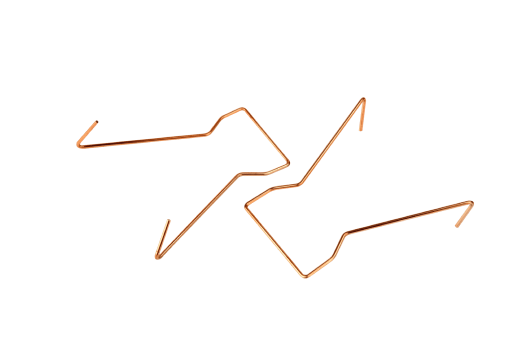

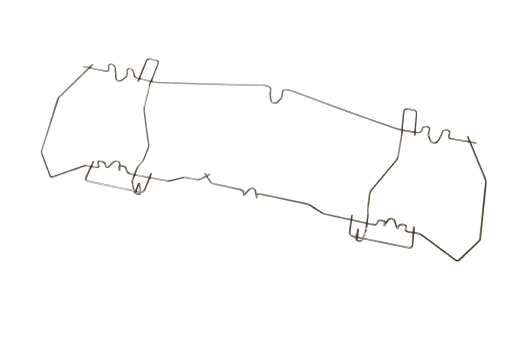

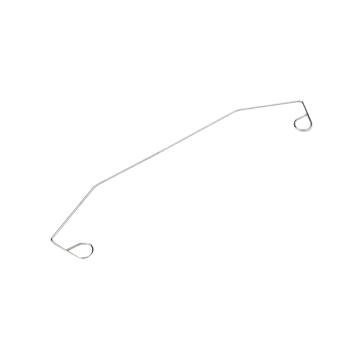

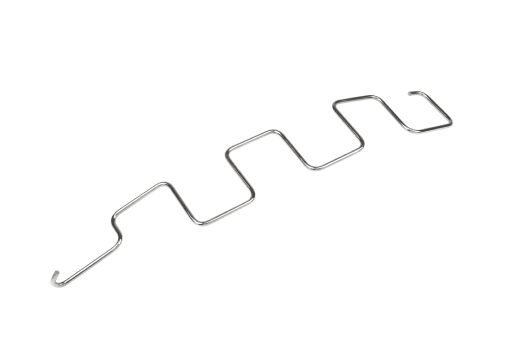

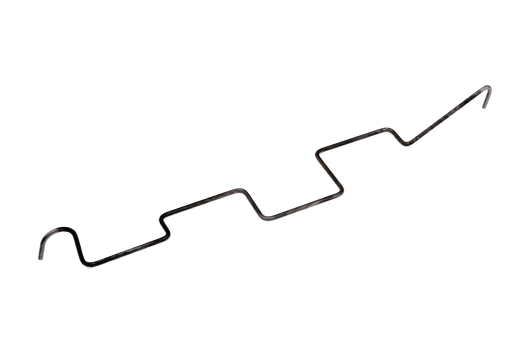

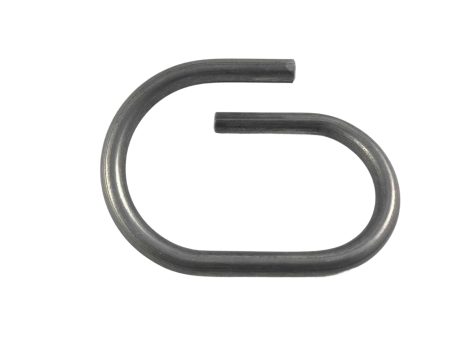

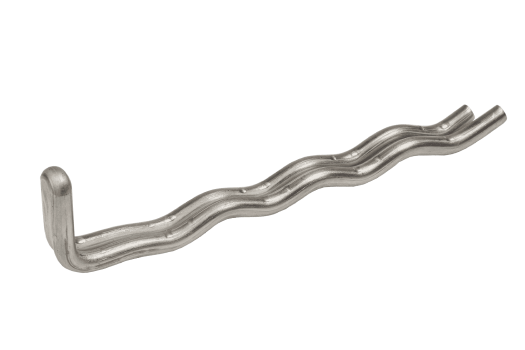

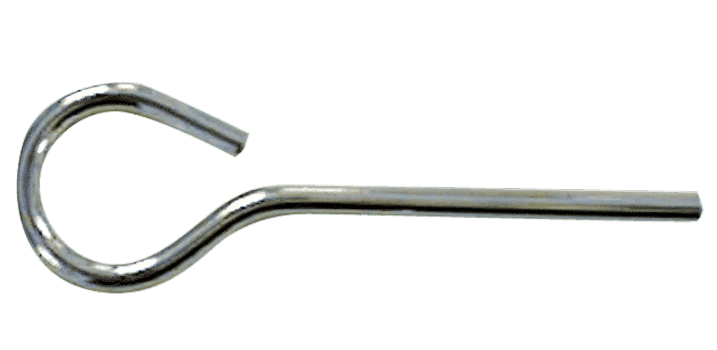

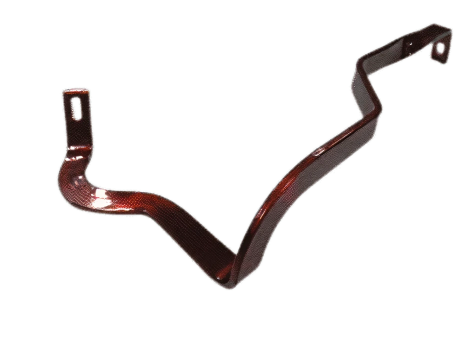

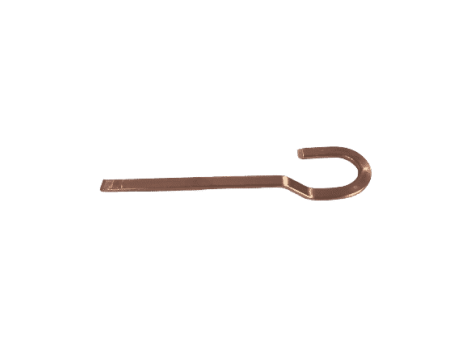

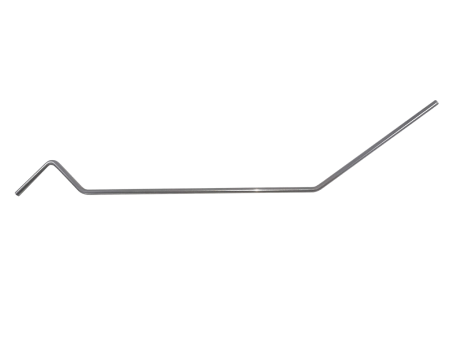

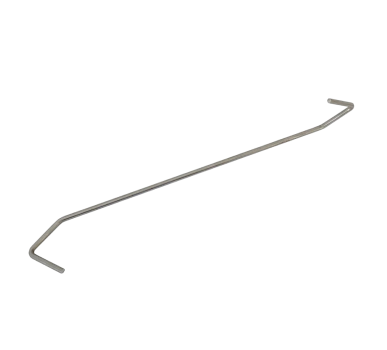

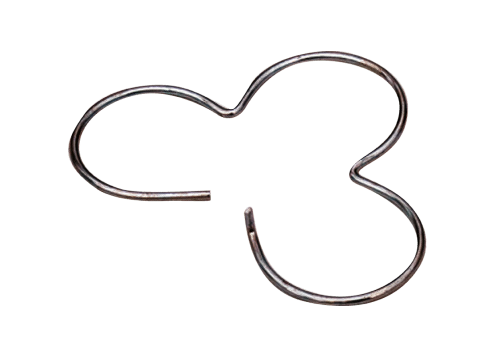

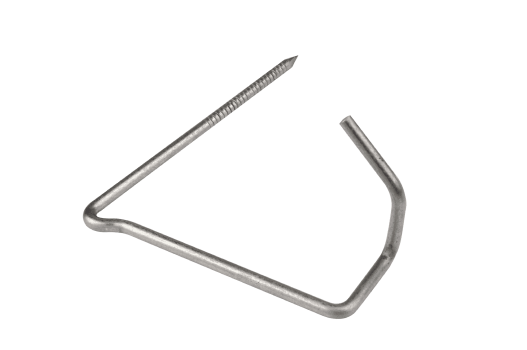

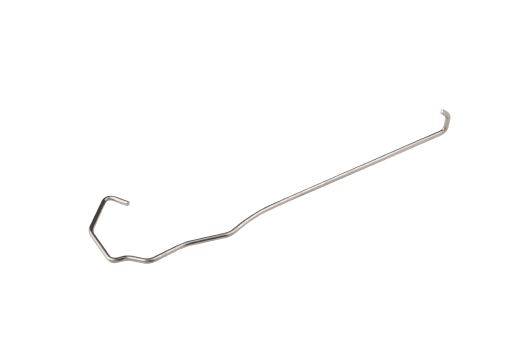

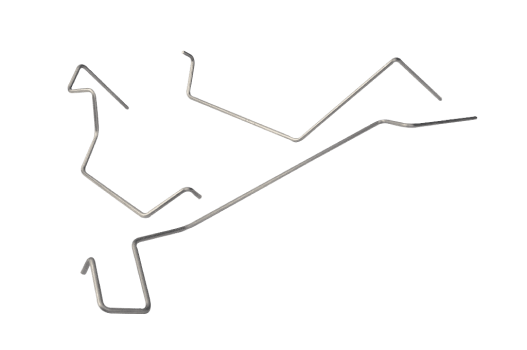

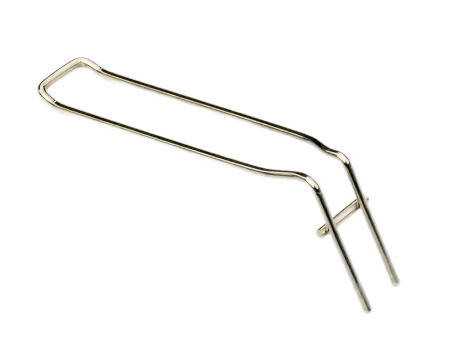

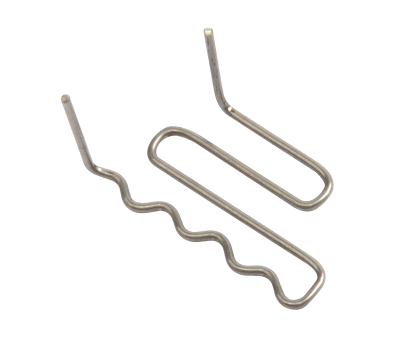

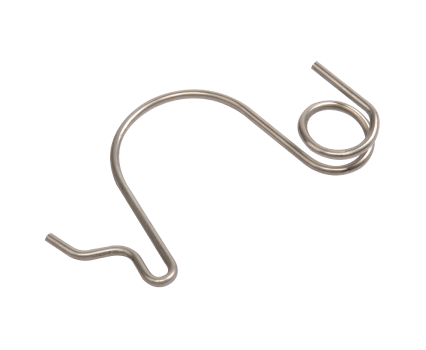

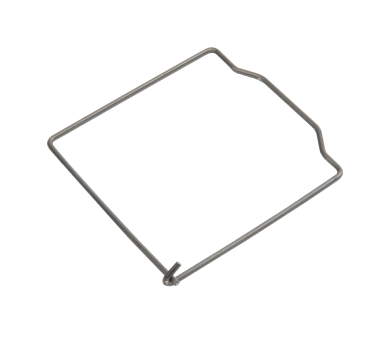

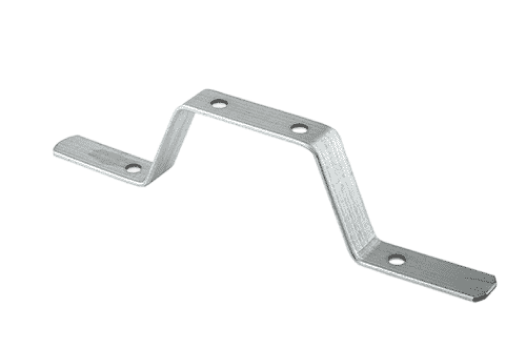

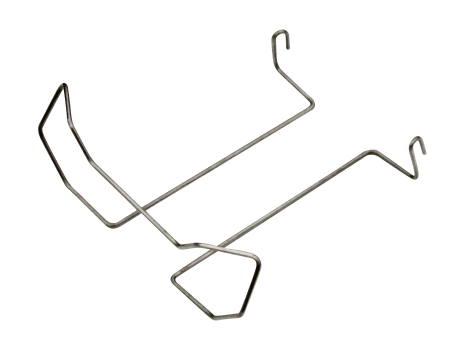

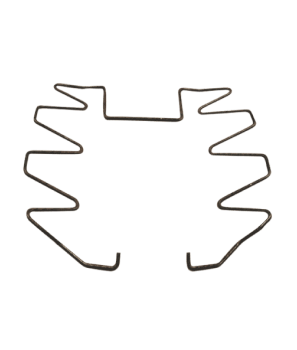

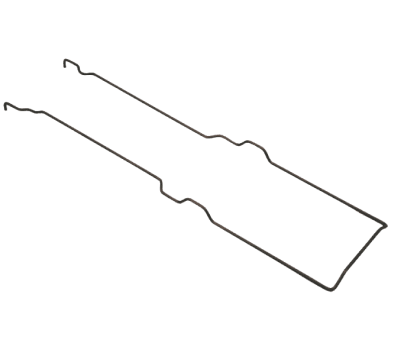

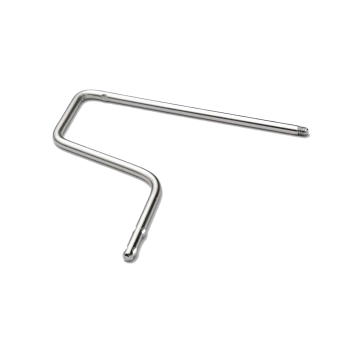

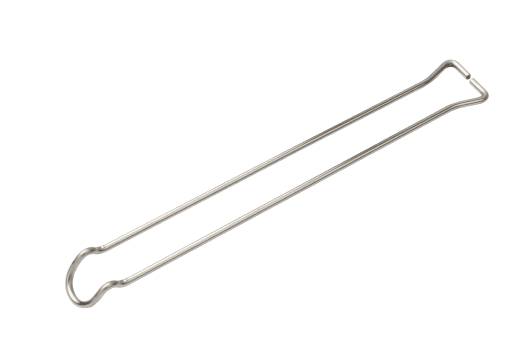

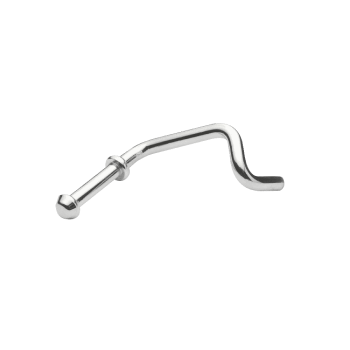

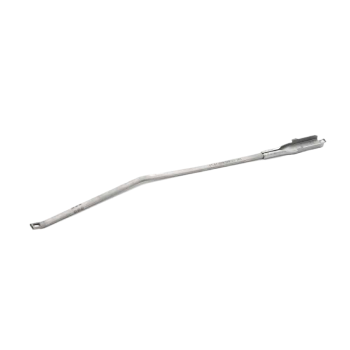

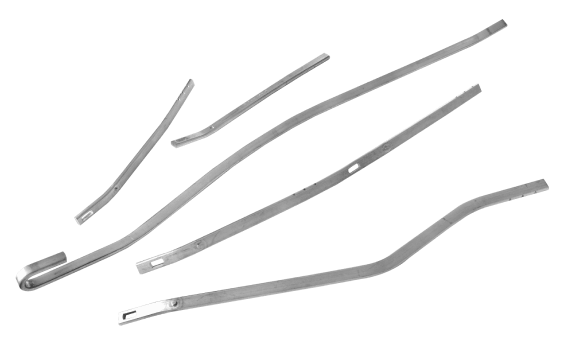

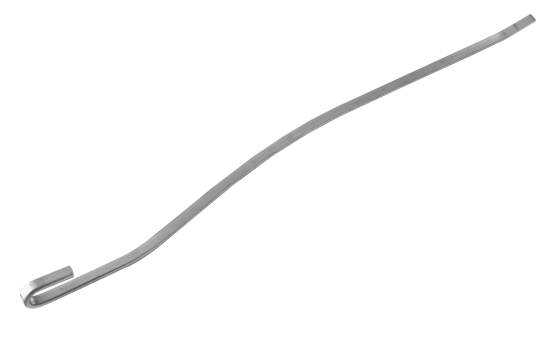

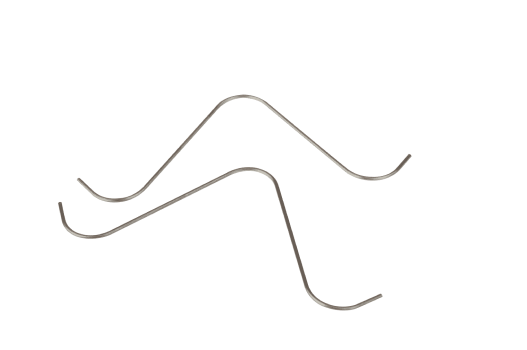

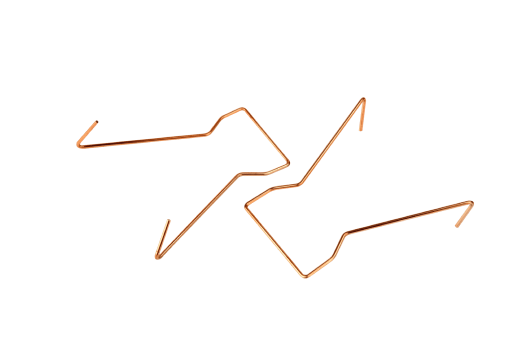

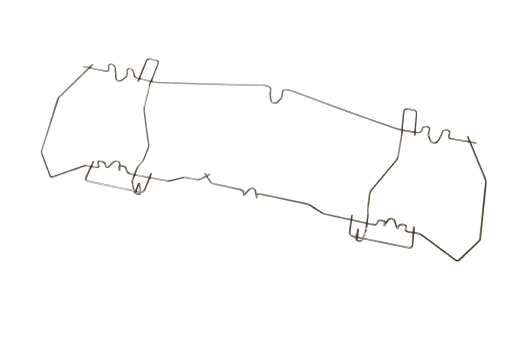

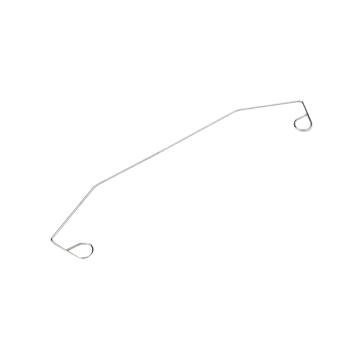

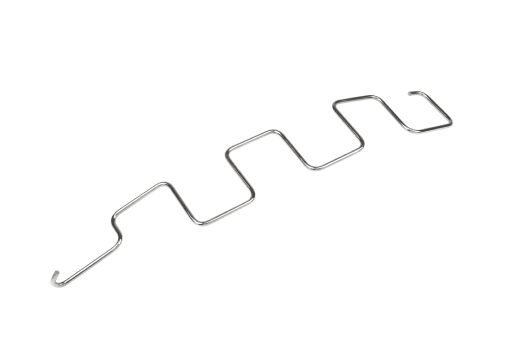

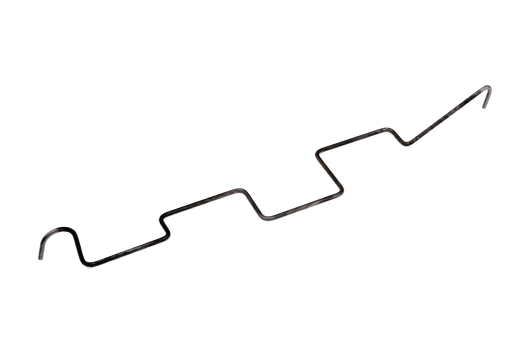

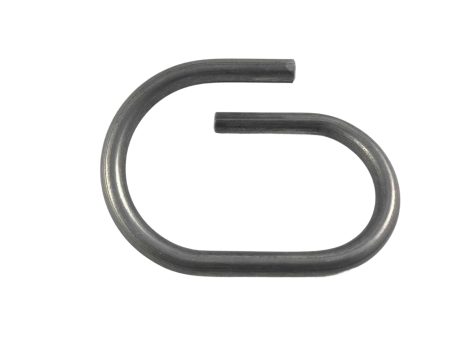

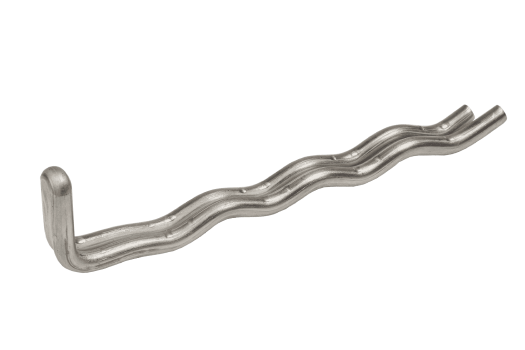

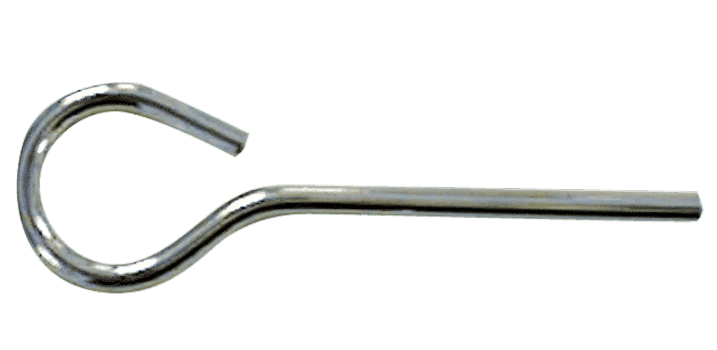

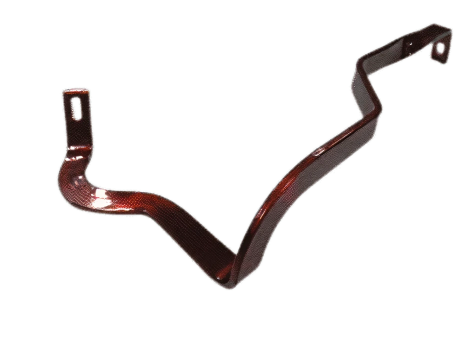

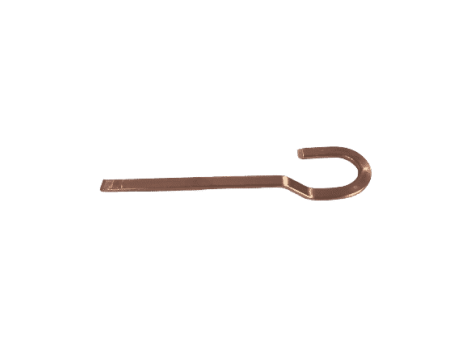

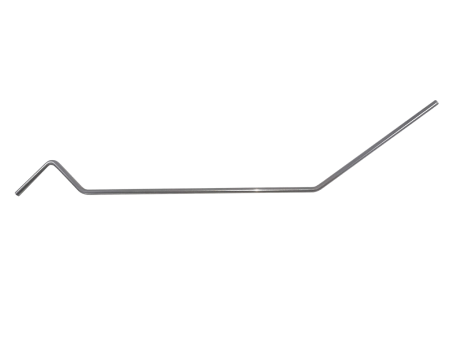

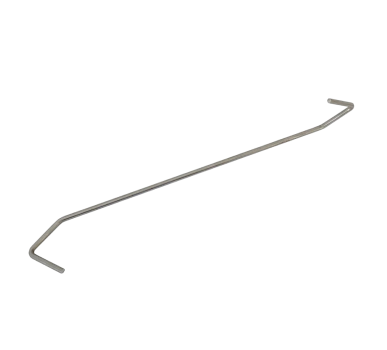

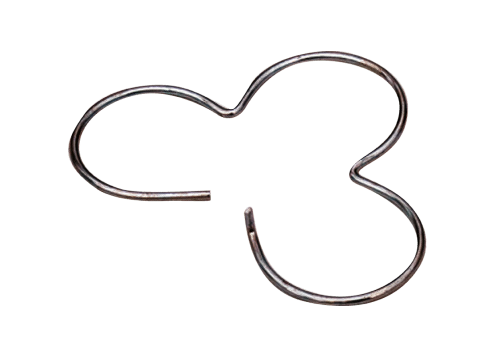

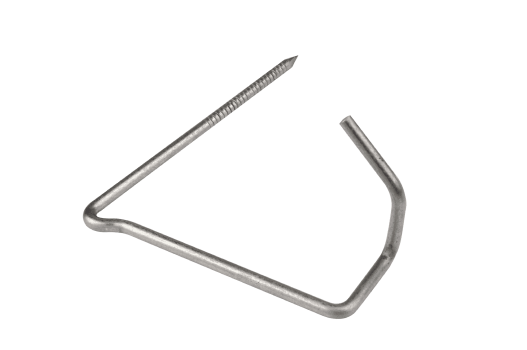

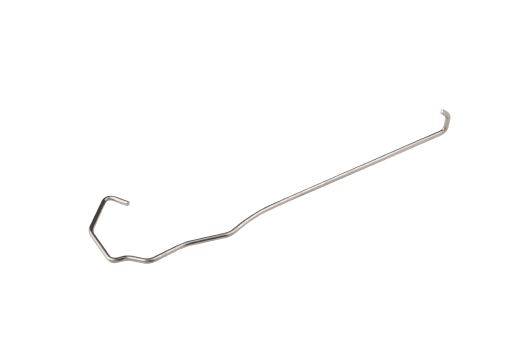

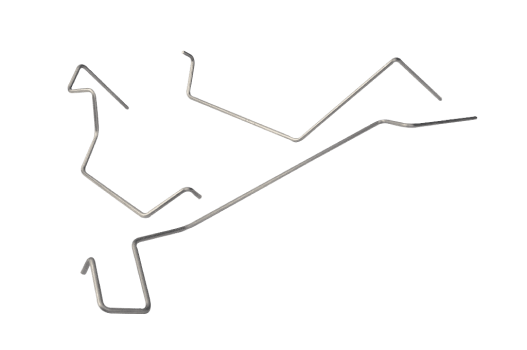

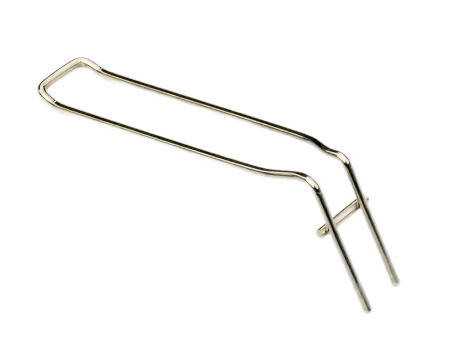

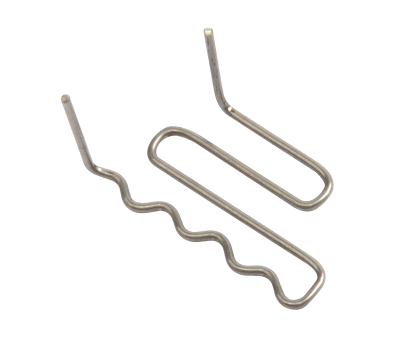

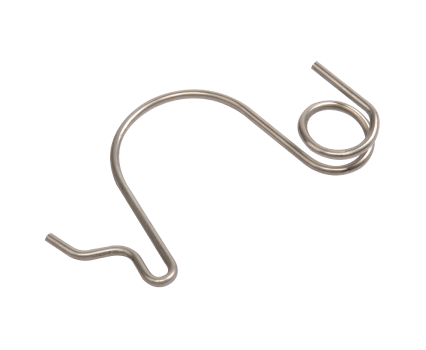

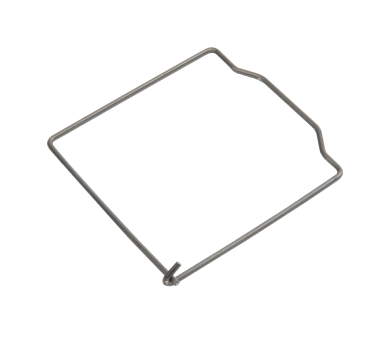

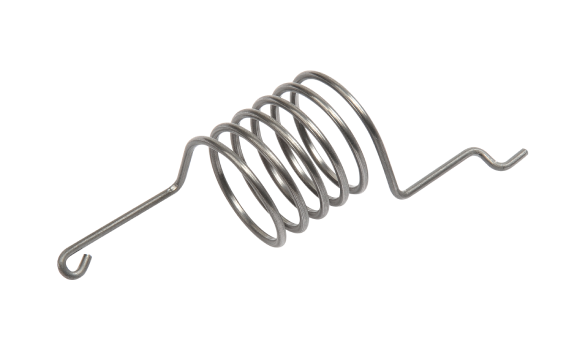

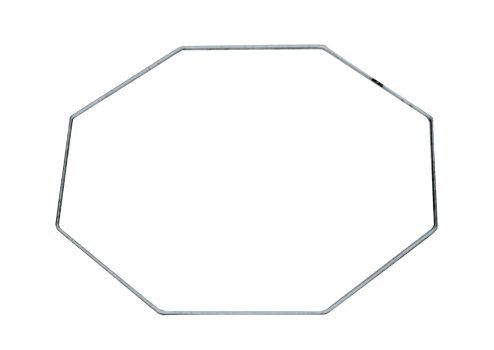

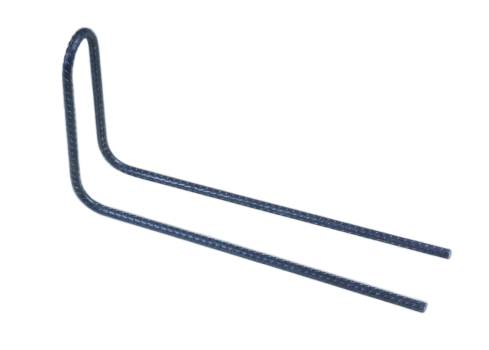

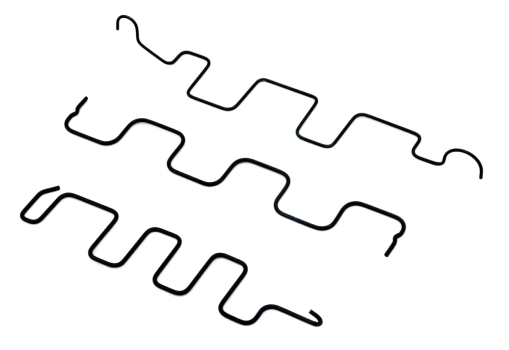

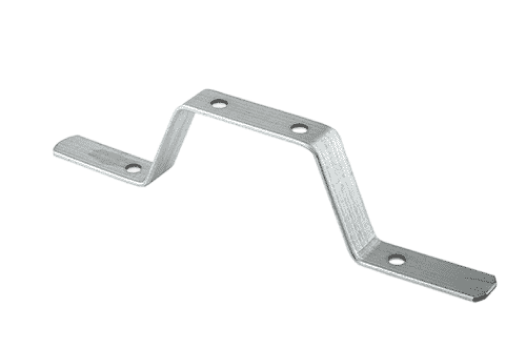

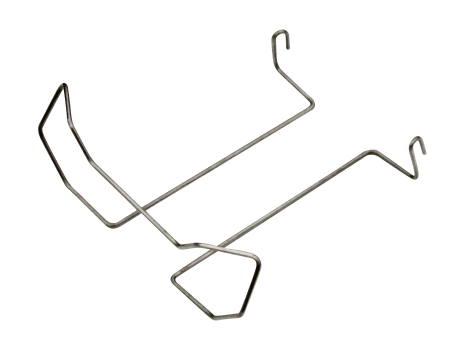

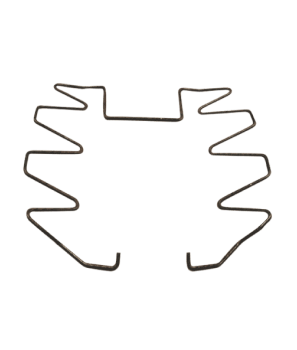

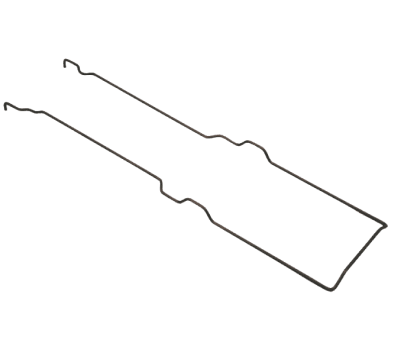

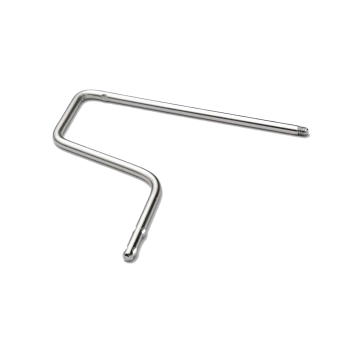

Parts that speak for themselves

Why choose our CNC wire bending machines?

Unmatched precision

Our CNC wire bending machines ensure precise bending, even for complex geometries.

Maximum flexibility

Adaptable to various diameters and configurations, our machines meet every need.

Low energy consumption

Our all-electric wire bending machines reduce energy consumption while delivering high performance.

Proven reliability

Over 30 years of durability, ensuring continuous production and minimal maintenance.

Innovative technology

Pioneers in electric technology, our machines integrate cutting-edge patented innovations.

Optimized productivity

Reduce cycle times while maintaining consistent quality for better efficiency.

Numalliance wire bending machines and the era of Industry 5.0

At Numalliance, we bring your workshops into the era of Industry 5.0, where the collaboration between humans and machines enables unparalleled performance levels.

Our wire and flat stock bending machines, designed to integrate smart technologies, offer you a unique combination of precision, flexibility, and advanced customization of your production processes.

Thanks to our digital innovations and the integration of secondary operations such as chamfering, welding, or punching, our bending machines adapt to each client’s specific requirements.

Industry 5.0 is not just about automation: it places the operator at the heart of the process, overseeing machines capable of predicting maintenance, controlling quality in real-time, and efficiently managing multi-reference production.

Numalliance solutions have already enabled our clients to boost productivity, improve bending quality, and reduce scrap.

With Industry 5.0, we go even further, creating a smooth and intelligent interaction between humans and machines, for a high-performance, durable, and connected wire production.

Dive into the world of Numalliance wire bending machines. Discover how our solutions combine precision, speed, and adaptability to meet the most demanding wire and flat stock forming requirements.

Expertise at the service of your production

With over 30 years of experience in wire and flat stock forming, Numalliance is a leading player in the design of all-electric CNC bending machines.

Our expertise, supported by proprietary and patented technologies, allows us to offer tailor-made solutions perfectly suited to the requirements of each client, regardless of their industry.

Renowned for our reliability and innovation, we help our clients optimize their production with robust, precise, and scalable bending machines.

We continuously invest in R&D to remain at the forefront of technological advancements and provide high-performance, durable equipment that meets the future standards of the industry.

Choosing Numalliance means trusting recognized expertise in bending, with industrial solutions designed to meet today’s challenges and anticipate those of tomorrow.

MIB by Numalliance JEC World

MIB by Numalliance, expert in the design and manufacture of hydraulic and electric presses for metal and composite processing, will be present at JEC World 2025, the world’s largest trade show dedicated to composite materials.

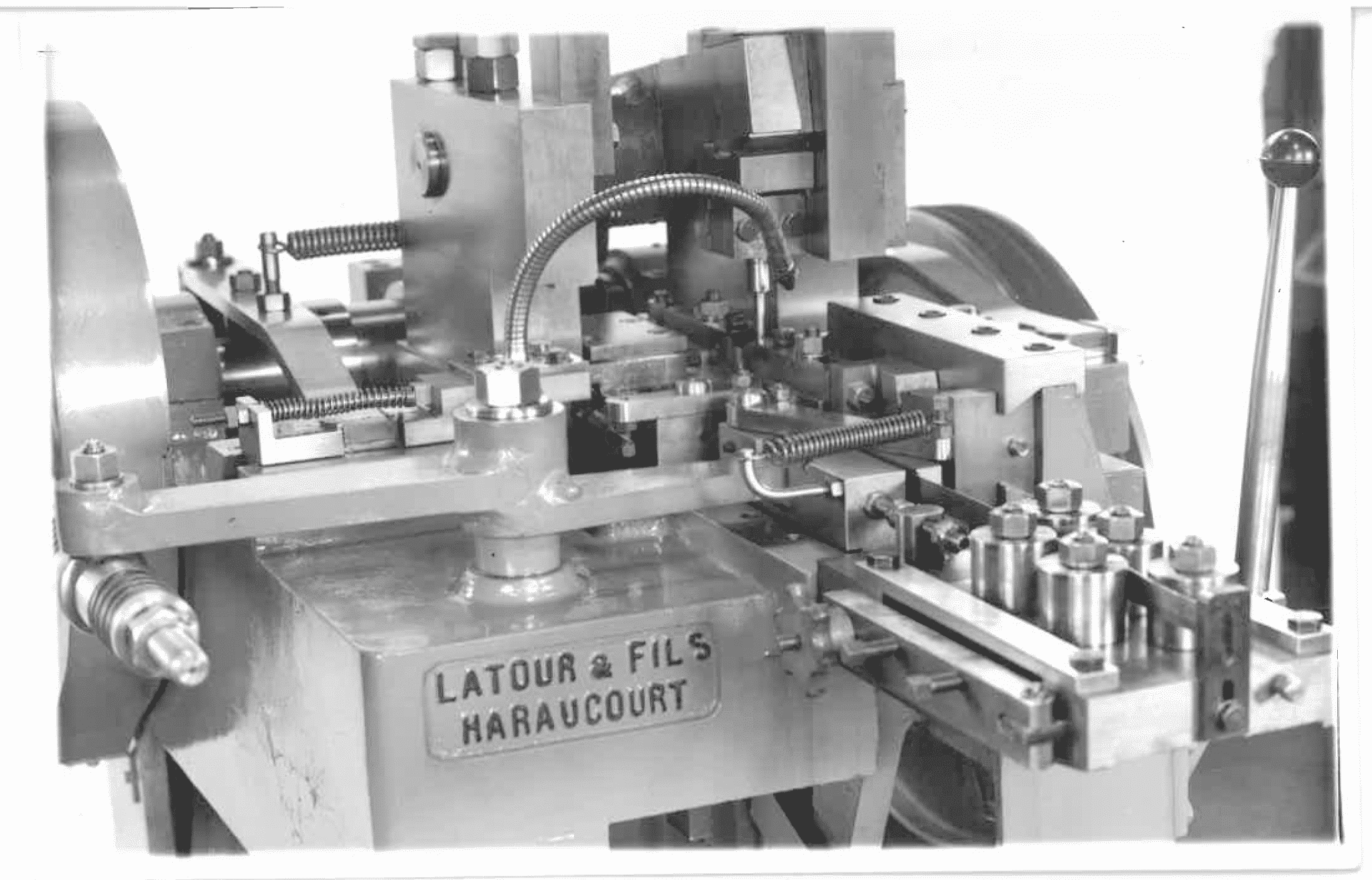

How does the experience of “Latour et Fils” exemplify the fundamentals of Numalliance, the “Made In France” for wire, tube and strip bending machines?

Thanks to his Openness, Respect and Ingenious spirit, Justin Latour, who founded Latour et Fils in 1872 and developed wire, tube and strip bending machines, was able to best meet the requirements

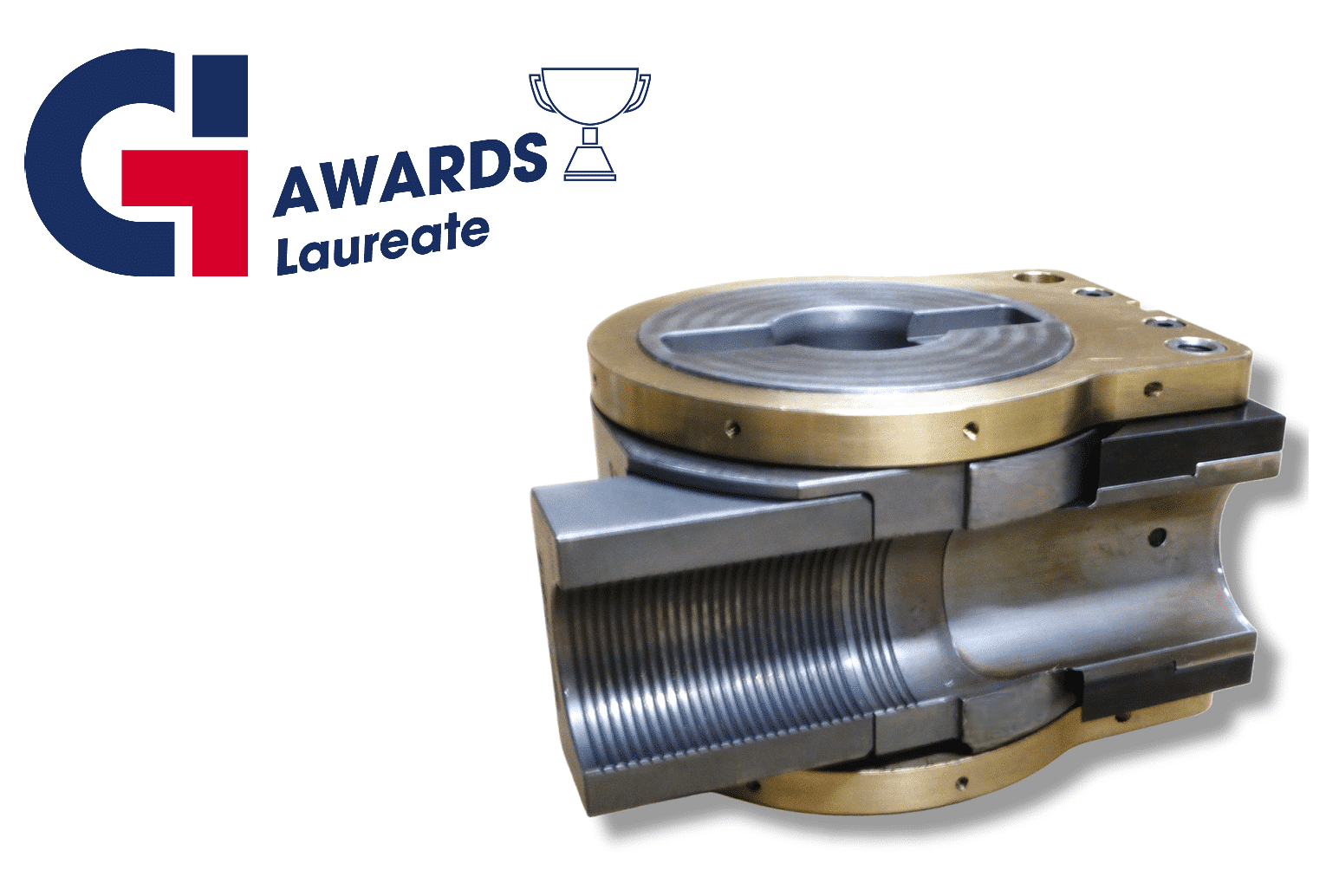

Global Industrie Awards: Bend die with integrated Wiper Die

Specialized in the production of bending tools for more than half a century, Numalliance group posseses numerous patents in the world of tube bending and still keeps innovating! Our latest innovation, focussed

Our experts are here to assist you. Whether you want to learn more or discuss a tailored solution, feel free to contact us.