Leading manufacturer in productivity solutions for wire, tube and flatstock forming

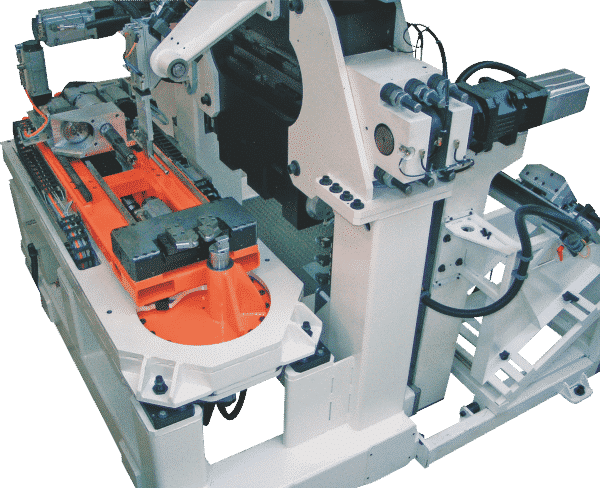

With the expertise, history and experience of 9 brands gathered under one banner Numalliance is dedicated to satisfy your needs. From standard or custom built machines and workcells for tube, wire and flat stock bending, to special hydraulic presses, and all other secondary operations your end product might require.

Leading manufacturer in productivity solutions for wire, tube and flatstock bending, Numalliance conceives and realises standard or custom-made installations, integrating ancillary operations such as endforming, flattening, punching, assembly, welding, upsetting, chamfering, machining, threading… as well as inline dimensional control and self correction.

You are a producer of metal part in wire, tube or flatsotck parts, and look for a cost effective way of doing so. Numalliance will innovate with you and propose the optimized and high-performance solutions tailored to your specific objective