| TE25 | TE25LR | TE32 | TE32LR | TE42 | TE50 | TE50LR | |

|---|---|---|---|---|---|---|---|

| Max tube ø | 1x.08" at 58 Ksi / 25,4x2 mm at400N/mm² | 1x.08" at 58 Ksi / 25,4x2 mm at400N/mm² | 1.25x.08" at 58 Ksi / 32x2 mm at 400N/mm² | 1.25x.10" at 58 Ksi / 32x2,5 mm at 400N/mm² | 1.65x.10" at 58 Ksi / 42x2,5 mm at 400N/mm² | 2x.08" at 58 Ksi / 50x2 mm at 400N/mm² | 2x.08" at 58 Ksi / 50x2 mm at 400N/mm² |

| Tube length | 79 to 157" / 2000 to 4000 mm | 79 to 157" / 2000 to 4000 mm | 79 to 157" / 2000 to 4000 mm | 79 or 120" / 2000 or 3000 mm | 79 to 157" / 2000 to 4000 mm | 79 to 157" / 2000 to 4000 mm | 79 or 120" / 2000 mm |

| Max bending raidus | 6" / 150 mm | 5" / 125 mm | 6" / 150 mm | 6" / 150 mm | 6" / 150 mm | 6" / 150 mm | 6" / 150 mm |

| Bending tools | 4 Left or right | 4 Left and right | 4 Left or right | 2x3 Left and right | 3 Right | 4 Left or right | 2x3 Left and right |

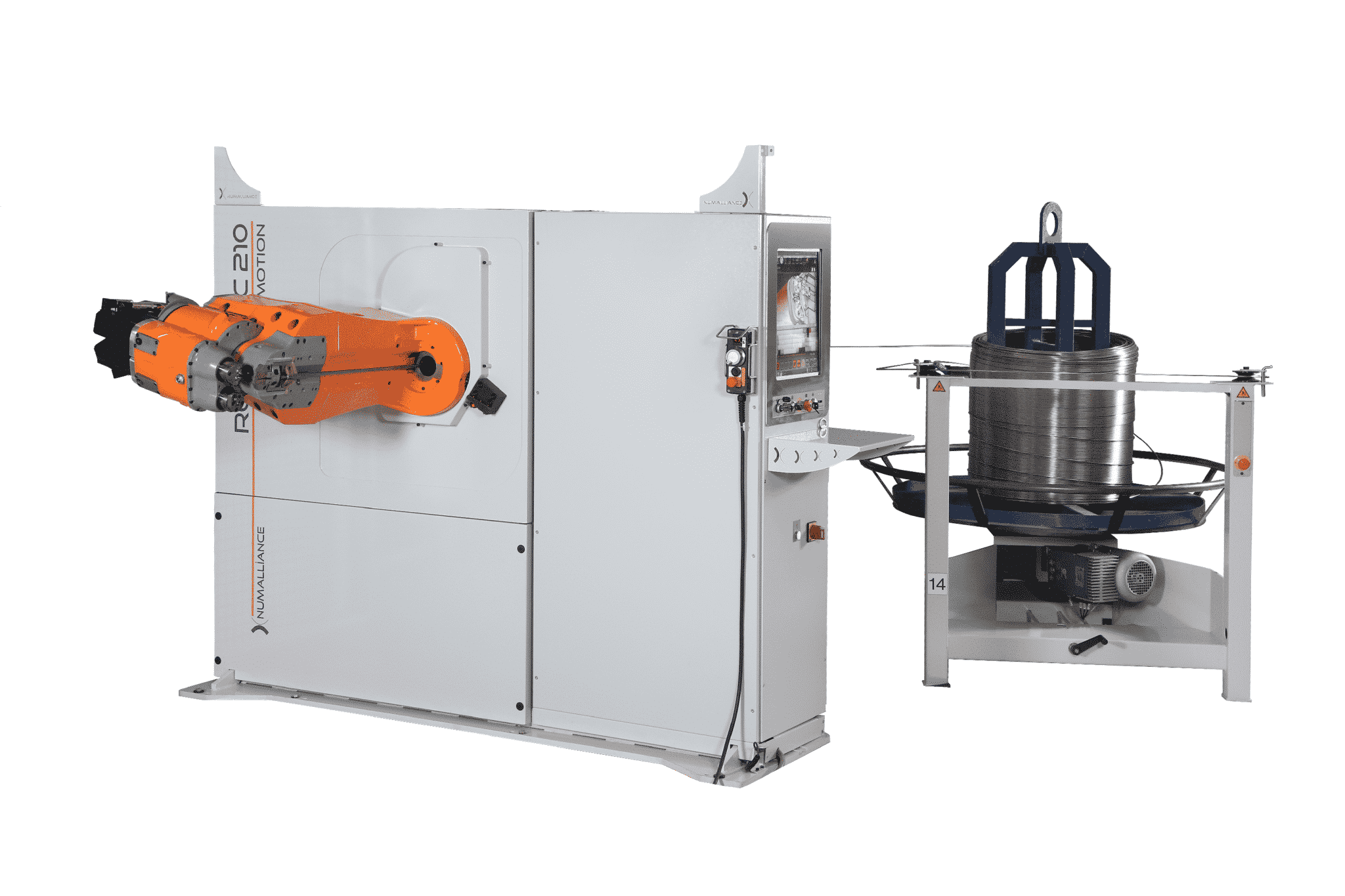

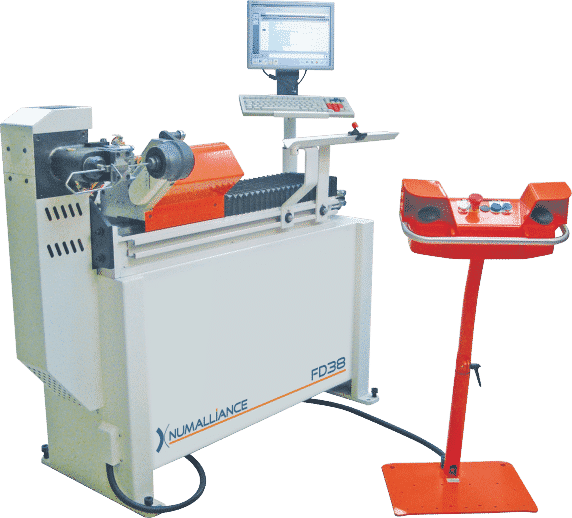

Main features

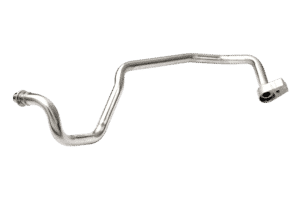

- From .40″ to 2x.08″ / 10 to 50×2 mm

- Applications : Automotive H.V.A.C., ERG Tube, structure parts, fuel, seats

- Air et Space : hydraulic piping, circulation control wing, fuel, structure

- Main features : all electric benders

- Stackable multi-radii

- Draw bending with and without mandrel and roll bending

- Possibility to combine bending with complementary operations

Man / Machine interface

- Industrial-Grade PC powered by proprietary software

- Multilingual dialog and programming interface on a 19″ touch screen

- Simulation program

- Additional I/O

- Internet connection: remote assistance and chat room

- Auto-corrective feedback from 3D-measuring devices

- Tool editor allows programming of complex parts

- Simulation tool to facilitate part set-up

- Program execution in slow motion

Discover our other CNC machines

Leading manufacturer in productivity solutions for wire, tube and flatstock forming

With the expertise, history and experience of 9 brands gathered under one banner Numalliance is dedicated to satisfy your needs. From standard or custom built machines and workcells for tube, wire and flat stock bending, to special hydraulic presses, and all other secondary operations your end product might require.

Leading manufacturer in productivity solutions for wire, tube and flatstock bending, Numalliance conceives and realises standard or custom-made installations, integrating ancillary operations such as endforming, flattening, punching, assembly, welding, upsetting, chamfering, machining, threading… as well as inline dimensional control and self correction.

You are a producer of metal part in wire, tube or flatsotck parts, and look for a cost effective way of doing so. Numalliance will innovate with you and propose the optimized and high-performance solutions tailored to your specific objective

Numalliance is here to understand your needs and respond effectively