E-mobility, a word we hear more and more often, but what does it really mean ?

E-mobility or electric mobility is a booming business sector. Its characterizes preserving the environment by reducing the carbon footprint of each travel and improving everyone’s quality of life, notably by manufacturing parts for the automotive sector intended for electric and hybrid vehicles, bicycles and scooters.

At a time when environmental degradation and the depletion of fossil fuels are at the heart of the topics of concern, preserving the environment has become a predominant issue in the strategy of industrial companies in the automotive sector. Which is why many of them decided to adapt their production to meet the new demands of the electric mobility sector.

Numalliance likewise has decided to support its customers by adapting its range of machines thus offering state-of-the-art productivity solutions dedicated to this new sector that needs parts that meet every specification precisely.

Numalliance solutions at the service of e-mobility

Historically being a partner of the automotive industry, Numalliance is well aware of the various constraints and problems faced by its customers and thus knows how to adapt its response in order to find optimal solutions, whether manufacturing parts for private vehicles, buses or trucks or even other smaller sized means of transport such as bicycles.

Numalliance’s R&D teams integrated all these criteria received as part of customer requests to develop various production tools to meet the needs of the e-mobility sector. Thus, our wire and flat bending machines can produce large quantities of busbars and hairpins.

Do you produce or wish to produce this type of part but do not know which machine to turn to? Numalliance guides you :

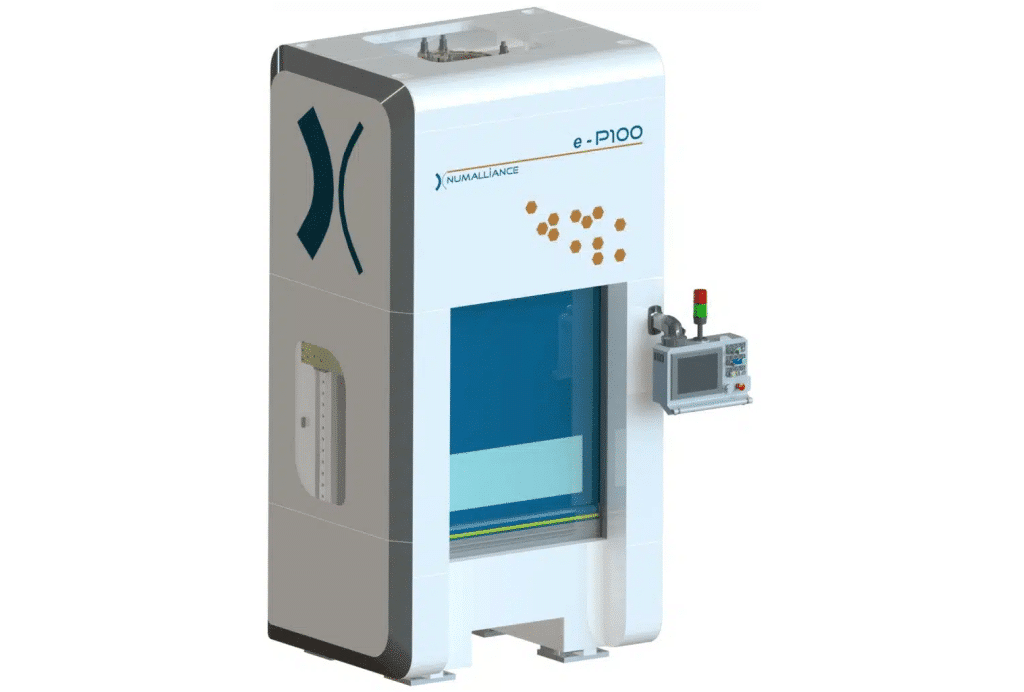

The FPX Busbar, developed to meet all your specific bending needs on copper and aluminum flat stock

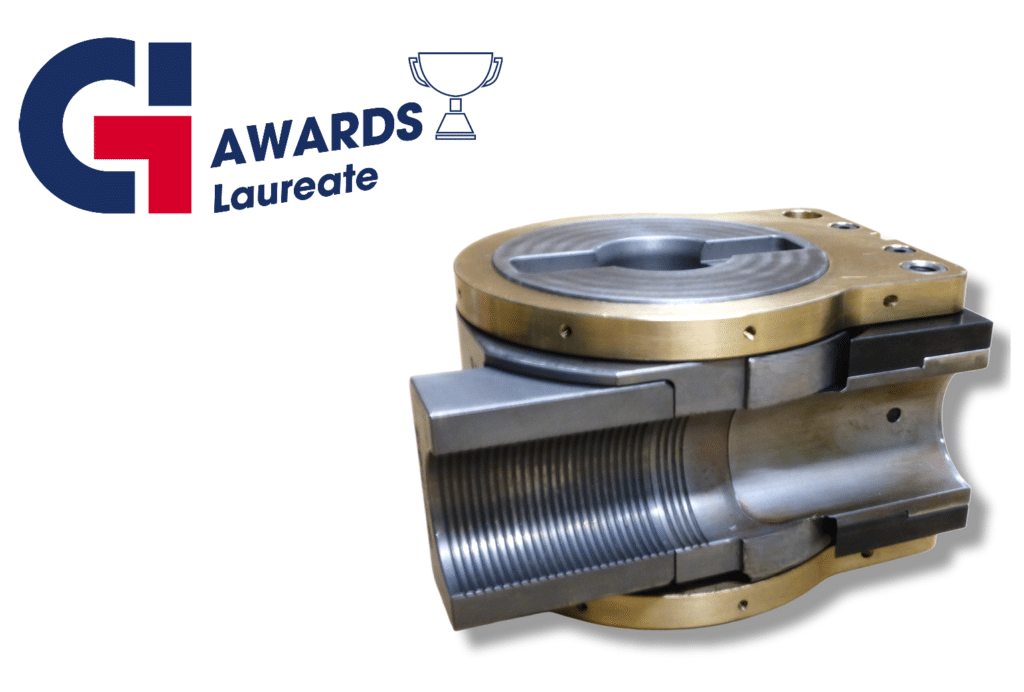

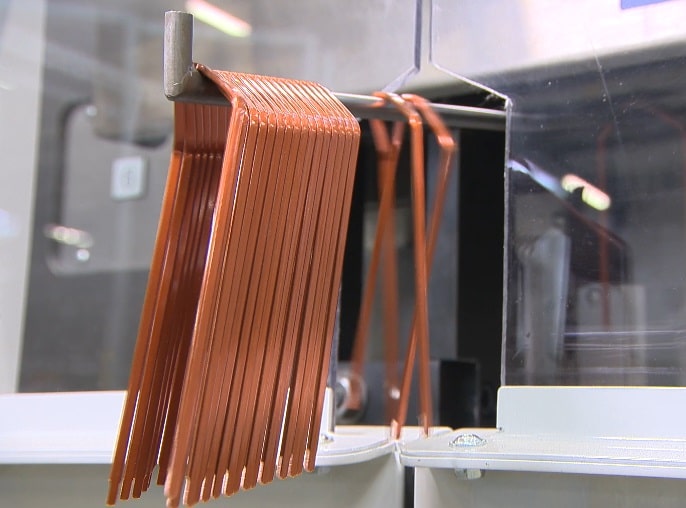

Also referred to as Omnibus, the busbar is a component that conducts very high intensity electricity between the battery and the motor of electric and hybrid vehicles.

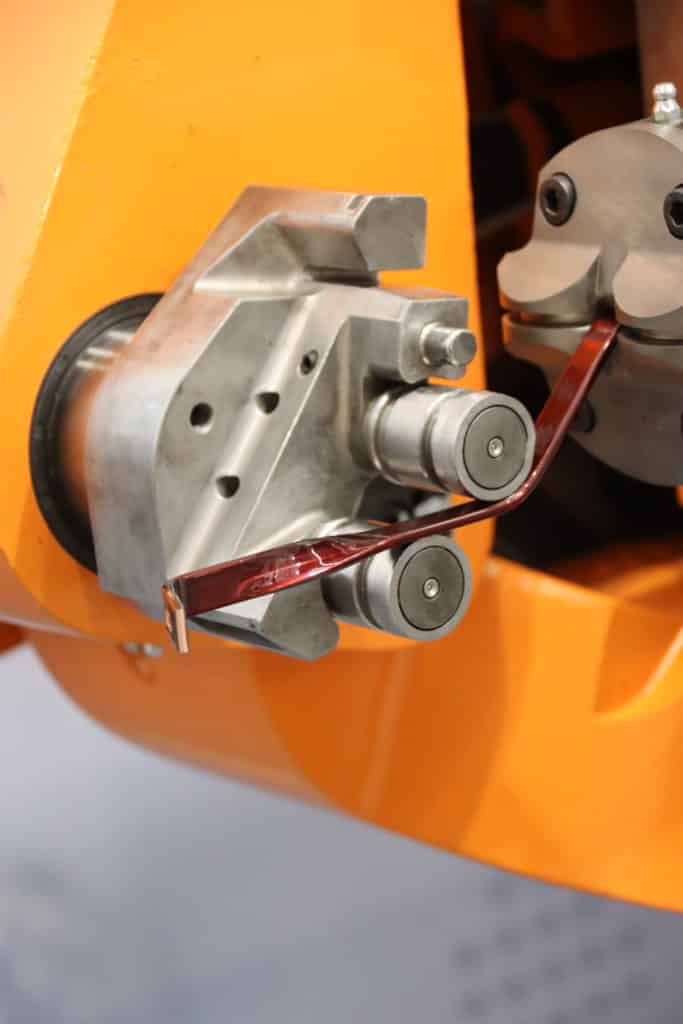

It can be produced on our FPX Busbar, a flat-stock bending machine with high precision for making close, double and even twist bends. The FPX Busbar is able to bend flat-stock parts from 9x3mm up to 25x8mm and has various options for secondary operations such as stripping, punching, marking as well as part check.

Owing to its specially design material feed system, the FPX Busbar respects the integrity of the material regardless of its type and coating. Highly flexible with coupled with ease of production change-over, the FPX allows you to make many other part references as well.

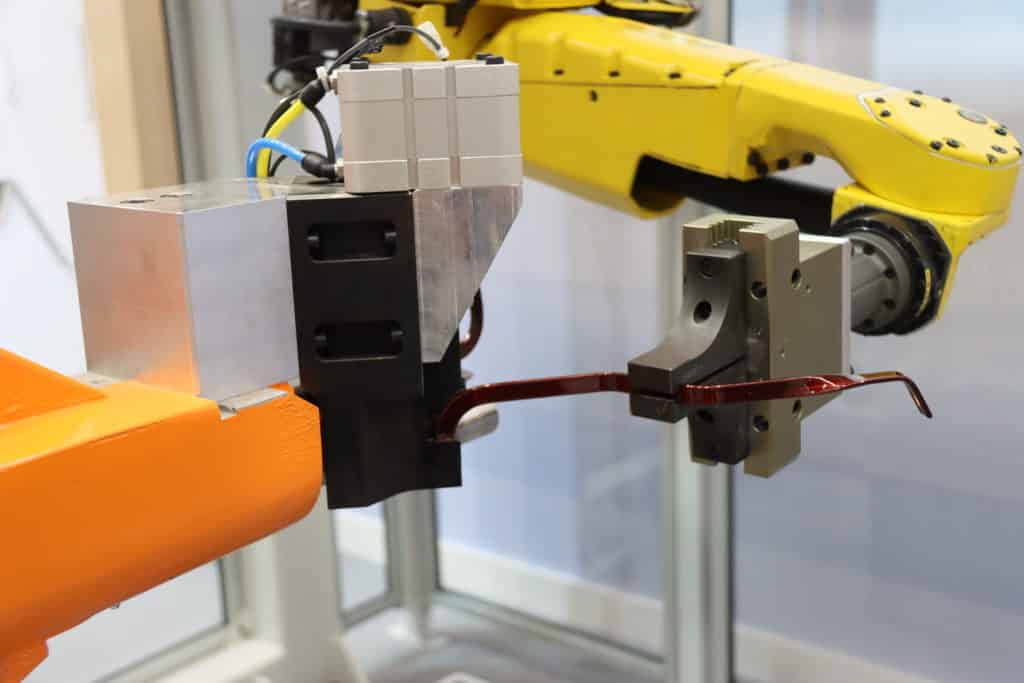

The speed of a Numaslide for the production of Hairpins

Key part of hybrid and electric vehicle propulsion systems, hairpins can be in 2D or 3D form and of different sizes. For the production of these parts, the Numaslide multi-slide bender is the ideal solution combining flexibility and speed, some references being produced at rate of less than a second per part. This bending machine also allows secondary operations such machining, finished part handling, marking and control.

The choice of a numerically controlled machine designed specifically to meet the requirements of the e-mobility or electric mobility sector, such as the FPX Busbar or the Numaslide, allows savings in raw materials compared to currently existing conventional solutions due to a perfect control of the part production process.

In addition to its remarkable bending, stripping and cutting capabilities, these machines in Numalliance’s new range can be easily integrated into fully automated production cells. High-performance solutions in terms of software (simulation, HMI, control, etc.) are also integrated into the machines, thus making it possible to obtain a complete productivity solution, a showcase for Industry 4.0.

You have a project, a question, do not hesitate to contact our specialists :